RUDALTOTO : Resmi Link Login Rudal Toto Akses Alternatif Situs Rudal Togel Terbaru

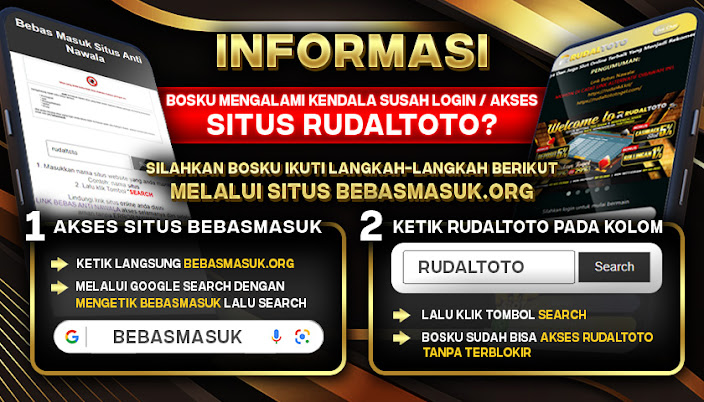

Sedang mencari situs rudal toto togel terbaru? kesusahan mencari link loginya tenang di situs ini anda sudah tepat menemukan situs login rudal toto resmi , juga sebagai link alternatif untuk masuk ke akun rudal toto togel.

Sebagai situs togel terbesar di indonesia, tentunya sangat banyak website yang menirukan situs rudal togel, maka dari itu bijaklah dalam mengakses akses situs rudaltoto, anda bisa mengetikan rudal toto sebagai alternatif untuk dapat login ke situs rudal togel online.

Bonus

Bonus

Login

Login

Daftar

Daftar

Whatsapp

Whatsapp

Live Chat

Live Chat